WHAT DIFFERENCE WILL SMARTX MAKE?

Implementation of quality by design principles

SmartXTM eases the burden of full and proper implementation of Quality by Design (QBD) principles, by giving teams access to error-free, good manufacturing data from all stages of the development process.

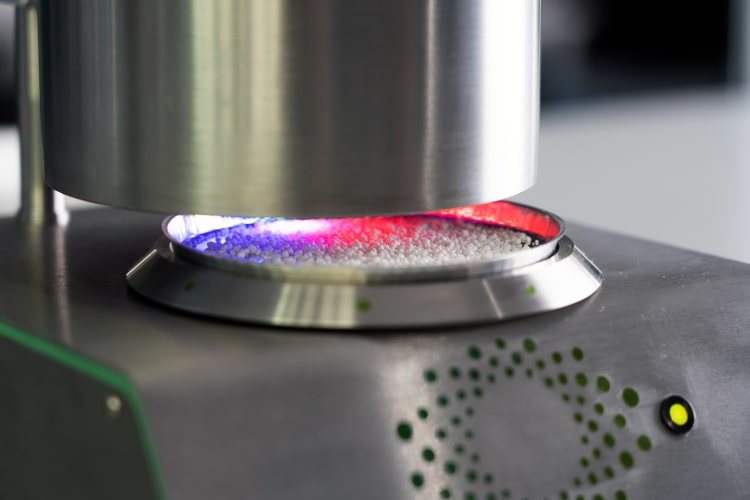

Human-error related experimental failures and deviations are prevented by pre-configured parameters and scheduling of experiments. All data, whether collected from the fluid bed system, PAT sensors, environmental sensors or LIMS (laboratory information management system), is integrated seamlessly.

Real Time Data Insights

Regulatory guidelines and the introduction of Quality by Design practices, have challenged the pharma industry to understand more fully the relationships between input raw materials, formulation, process design and product performance.

Greater understanding will minimise unexpected surprises when development processes are scaled up to commercial manufacturing.

Our SmartX platform integrates real-time data from disparate analytical tools into a unified visual dashboard, cloud-based analytics tools enable batch-to-batch trending and easy access to data for regular reporting and process optimisation.

PROCESS DATA NEEDS TO BE:

- Consistently recorded

- Organised and analysed

- Accessible to all team members as the process is refined and agreed