TYPES OF PARTICLE SIZE ANALYSERS

Pharmaceutical Industry

The analysis of particles and the characterisation of their size and shape is critical in a variety of industries, including food, construction, biopharma, and pharmaceutical. The size of the granules used in the production of capsules, tablets, and effervescent tablets affects the disintegration rate, dissolution rate, and absorbance rate.

The most common methods for determining particle size are:

- sieve analysis

- laser diffraction

- dynamic light scattering

- direct imaging techniques

When examining the same samples, the results of these methods frequently do not correlate well. This is due to differences in the fundamental measurement principles employed by each method in determining particle sizes.

Comparing the fundamental operating principles of sieve analysis, laser diffraction, dynamic light scattering and direct imaging will help us gain a better understanding of the differences in results as measured by each method.

Sieve Particle Analysers

Sieve analysis is a method of determining the particle size distribution of a material.

The process separates fine particles from more coarse particles by passing the material through a number of sieves of different mesh sizes, essentially fractioning particles within certain sieve bin sizes. Wet sieving is suitable for particle sizes from 20μm up to 3mm while dry sieving can be used from 30μm up to 125mm.

Limitations of Sieve Particle Analysers

Sieve analysis can be very simplistic in its principle and operation but it is not without its limitations in measurement.

- For elongated and flat particles, a sieve analysis will not yield reliable mass-based results.

- It does not account for particle shape effects of different particles.

- Sieve analysis may not have the ability to provide high resolution for a sample with a narrow distribution owing to the limited range of mesh sizes available.

- No further particle shape information is available from sieve analysis without additional examination of the particles using other measurement methods.

- This method does not have the ability to analyse single particles.

- Sieve analysis has longer measurement times and a lower measurement speed than that of laser diffraction or direct imaging.

- Sieves are prone to blinding. This is the obstruction of the sieve openings by the material that is being analysed. It occurs as a result of particles of the same or similar diameter to the sieve openings becoming lodged within the apertures of the sieve. This reduces the available openings for other particles to pass through and can result in particles that are smaller than the sieve apertures being trapped on that sieve. This will greatly affect the mass distribution and thus accuracy of the PSD.

- It’s also an offline method of particle size distribution and is lacking in any real-time ability for the monitoring of processes.

- No particle images can be obtained using sieve analysis.

Laser Diffraction

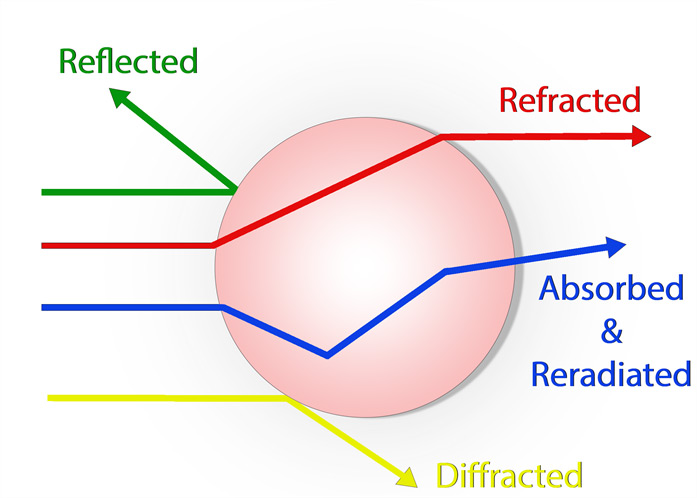

Laser diffraction is a technique for determining the particle size distribution (PSD) of a sample material by analyzing the scatter pattern of light from the sample. When light interacts with particles, it creates a scatter pattern, which an array of sensors detects and measures. Because the angle and intensity of the scatter pattern are proportional to particle size, it is possible to derive particle size information from the scattered light of an observed sample mathematically.

Particle size information for a given sample is presented as a volume fraction distribution based on the diameter of the observed particle’s sphere of equivalent volume.

Limitations of Laser Diffraction Particle Analysers

As with any scientific method, there are a number of limitations, caveats, and difficulties associated with this method.

To begin, a number of steps must be completed prior to analysis in order to obtain an accurate and reliable measurement using laser diffraction as a method of PSD analysis. Before the optical model can be established, the optical properties of the sample to be analyzed as well as the surrounding medium must be known. This can be a problem for new or composite materials, resulting in the establishment of the optical model throughout the process.

However, knowing the refractive index may preclude the use of laser diffraction because the models can only return accurate predictions of particle size at specific refractive indices for both the sample and the medium. As a result, determining the appropriate refractive indices required for accurate measurement is frequently a trial and error process.

Finally, laser diffraction particle size analysis is based on two assumptions. The first is that the particles are perfect spheres, and the second is that the material is homogeneous, resulting in a uniform refractive index. As the eccentricity of the sample changes, the assumption that all particles are spherical has an effect on the accuracy of particle measurement. The individual particle volume is calculated by assuming a perfect sphere when constructing the volume distribution of the sample; however, it has been demonstrated that the size of a non-spherical particle is larger than the equivalent sphere of the same volume calculated by laser diffraction (Jonasz, 1991). As a result, laser diffraction underestimates the volume of particles with high eccentricity.

In conclusion, laser diffraction as a method of particle size distribution analysis has the following drawbacks:

- Incorrect measurements can occur if the refractive indices used to build the optical model are incorrect.

- Assuming that all particles are perfect spheres can reduce measurement accuracy, as samples with high eccentricity reduce measurement accuracy.

- Non-homogeneous sample analysis can result in incorrect measurements due to changing refractive index values.

- The measurement time can range between 2 and 10 minutes.

- Testing must be done offline, which limits the use of laser diffraction as an in-process control method.

Dynamic Light Scattering

Dynamic Light Scattering (DLS), also known as Quasi-Elastic Light Scattering (QELS) and Photon Correlation Spectroscopy (PCS), is an optical method for determining particle size properties in a dispersed sample by observing the change in scattered light intensity over time.

Brownian motion (random motion of colloidal particles due to physical interactions/collisions with molecules in a solution) results in a constantly changing particle position and, as a result, a changing scattered light intensity for a stationary solution. The rate of change of light intensity is related to particle size distribution in the sense that small particles fluctuate more frequently, resulting in a faster change in scattered intensity.;

The change in scattered light intensity can thus provide information on the diffusion conditions within the sample for which the particle size relationship is understood. DLS is governed by the fundamental process of interference: when two waves interact, they can combine in such a way that the resultant wave is either an amplified or diminished superposition of the initially interacting waves.;

When scattered waves interfere constructively, the DLS detector records a high light intensity; when scattered waves interfere destructively, the detector records a low light intensity.

Some applications necessitate knowledge of a sample’s number, mass, or volume distribution. The MIE theory of light scattering is used to determine the number or volume distribution using DLS.

Unfortunately, there is no direct method of determining the mass distribution as the density of particles needs to be known. Further methods must be utilised to determine the mass distribution.

Limitations of Dynamic Light Scattering Particle Analysers

The following limitations are applicable to dynamic light scattering:

- The sample must be in solution.

- It is an offline method.

- Low resolution with closely spaced size populations with a difference of size of less than a factor of three, DLS will not precisely characterise a polydisperse sample.

- Multiple light scattering when one particle is scattered by another before reaching the detector can hinder accurate calculation of particle size.

- It is typically employed for particle sizes in the range 0.002 – 2µm.

- Very sensitive to temperature, solvent viscosity, and refractive index.

- Sensitive to contamination e.g. from dust.

Direct Imaging Particle Size Analyser

In real-time, the direct imaging particle size analyser measures the size and shape of particles ranging in size from 50μm to 5500μm. It is a non-destructive, non-product contact analytical instrument that can be used both as a bench-top laboratory instrument and as a process analytical technology in-line. The direct imaging method used by Innopharma Technology’s Eyecon2 captures images of samples that convey surface morphology and report shape information. This direct imaging particle size analyser can measure wet and dry powders as well as bulk solids. As it continuously captures and processes data in real-time, it also allows for the tracking of particle size growth and decrease in the process.

The Eyecon2 calculates particle size distributions based on individual particle measurements within a sample image.

These captured images are then processed by the EyePASS™ software, which uses a particle detection algorithm to identify and measure individual particles within the captured image.

It then records and calculates measurement data such as the D10, D25, D50, D75, and D90 as numeric and volumetric sizes with Mean and Median values, all of which are trended in real time with live histogram and S-curve results.

Limitations of direct imaging particle size analysers

The Eyecon2, like all other particle size measurement systems, has limitations that make it unsuitable for obtaining highly accurate measurements. Some of the areas where the Eyecon2 is limited in obtaining accurate and repeatable particle size measurements are listed below.

- Limits of detection of particles from 50 – 5500µm in size.

- Difficulty in obtaining accurate measurement results of dark particles without algorithm optimisation by user. This is a trial and error process and can take some time to optimise.

- The Eyecon2 relies on direct illumination of sample for particle identification within the algorithm and therefore transparent materials such as glass and some polymers cannot be accurately measured.

- Highly reflective particles are difficult to measure due to reflections.

- The focal length of the system is limited which means samples must be adequately close in order to appear in focus and measurable by the system.

- The depth of field is small which means that material with a very wide sample range distribution will be difficult to measure at the extremes of the distribution curve.

Conclusion

So if you are looking to:

- Capture the real-time data analysis of your bulk powder processes automatically.

- Troubleshoot and improve end-product goals with particle size and shape data.

- Adopt an automated process control to drive down production cost.

- Minimise risk associated with hazardous materials through non-product contact automation

then the Eyecon2, direct imaging particle size analyser, might just be what you’re looking for.

Contact form shortcode here

OUR PRODUCTS

SmartX

This is our accelerated development and advanced manufacturing platform for Fluid Bed Systems. It enables faster, more systematic process development and a more robust, automated approach to manufacturing.

Eyecon2

This is our market-leading particle analyser for powders and bulk solids. It utilises direct imaging technology for real-time particle size and shape information.

Multieye2

This is our multipoint, near infrared spectrophotometer for measuring changes in process. It measures intensity across a broad range of wavelengths and delivers an unparalleled level of process understanding and control.