How to Establish a Particle Size Specification for OSD Control

Possibly one of the key pillars to quality oral solid dosage (OSD) pharmaceutical manufacturing is particle characterization. The importance of particle size analysis in pharma manufacturing is significant. Particle variability, particularly particle size distribution (PSD), can substantially impact the flowability, blend uniformity, compressibility, dissolution rate and bioavailability of OSD. The result of these factors ultimately impacts the safety, efficacy, and quality of drugs. It is of no surprise that the importance of controlling and monitoring PSD in your process is among the highest priority in the pharmaceutical industry.

Breaking tradition

Typically, PSD is measured post-processing after a batch operation modifies the particle size or a sample is taken during processing to determine the process end-point. The industry standard to determine PSD is still regarded as sieve analysis, where a sample of material is taken and passed through a number different sized sieves. The amount is then collected from the sieves and weighed to determine its PSD.

Sieve analysis is considered an off-line method as samples are taken from the process as it is running. This method offers only a small window of representation of the state of the process, as PSD and other critical elements of information cannot be captured in real-time.

Due to the traditional nature of the method, sieve analysis can be slow, laborious, and analogue by nature as it does not permit real-time control of PSD, and also may offer limited process insight and low resolution. Such shortcomings increase risk in real-world settings, for example, when a batch of high-value drug powder can be put at risk due to limited control of the PSD within the batch.

The use of real-time measurement methods has been encouraged by regulators for nearly two decades, with the FDA having released their guidelines for the use of Process Analytical Technology (PAT) in the pharmaceutical space in 2004.

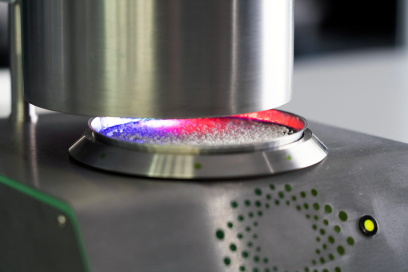

The benefits of measuring in-line for particle size measurement are significant. The inclusion of PAT tools allows for digitization of processes that enable them to output real-time data that offers a complete understanding of the process -not just estimations or small windows to draw inferences from.

Using PAT to generate a particle size specification

Developing particle size specifications and an effective means of controlling PSD in pharmaceuticals is often a hurdle for manufacturers. To meet regulatory standards, manufacturers must include analytical procedures, method validation, and acceptance criteria methods to establish particle size specifications and PSD controls.

As outlined by the United States Pharmacopeia, particle size analysis by a method such as sieving, follows the following steps:

- Sampling of bulk powders

- Sub-sampling of bulk samples for specimen

- Specimen preparation or dispersion

- Instrument set-up and verification

- Size measurements

- Data analysis and interpretation

- Report of size results

Establishing particle size specifications with PAT may be more a seamless process in contrast to traditional methods, such as sieve analysis. The elimination of manual sample preparation and presentation steps may reduce variability and increases robustness. At the same time, the inclusion of PAT can markedly improve control of PSD.

PSD is a Critical Quality Attribute (CQA) for many powder processes due to the impact it can have on content uniformity, dissolution, particle degradation, among others. Critical Process Parameters (CPP) are key variables in pharmaceutical manufacturing that can impact the production process and must be monitored for deviations that may affect CQA. For these purposes, the use of PAT to monitor and control both the CQA and CPP in-process is essential.

Still, to adhere to regulatory standards, data analysis and interpretation and the selection of an appropriate optical model is critical. For reproducibility, an optical model as well as the refractive index values (if applicable to the method of measurement) must be disclosed.

Validating particle sizing methods

Generally, the validation of an analytical method is conducted through a series of laboratory studies that gauge performance characteristics of the analytical method to ensure it meets requirements. However, as outlined in the International Council for Harmonization of Technical Requirements for Pharmaceuticals for Human Use (ICH) guidelines Q2A and Q2B, the validation for particle sizing methods differs from the validation of other analytical methods. Validation of particle sizing methods focuses on evaluating the repeatability, precision and robustness of the method and parameters such as range, linearity, accuracy, quantitation limit, specificity and detection limit are not typically required.

Acceptance criteria for particle sizing methods

When establishing acceptance criteria for a particle sizing method, the acceptance size range should correspond to the performance or manufacturability of the drug. A narrow PSD is targeted in pharmaceutical manufacturing of powders, however, if a broad range in PSD is desired, it is essential to control the entire size distribution within the process rather than the mean size alone. This becomes a critical factor in two-powder systems in which the same mean size may exist, but the different size distributions may impact the overall drug performance and drug manufacturability.

Particle size analyzers, such as Eyecon2, can use D10, D50 and D90 values as acceptance criteria. The D-Values derived from Eyecon2 correspond to the cumulative size distribution of the material in the process, whereby each D-value relates to particle size at which 10%, 50% and 90% of the sample material lie.

D-values can be used to establish a control strategy for PSD by fixing upper and lower limits to the D10, D50 and D90 values. Typically, a one-sided limit is not acceptable without adequate scientific justification. Fixing limits to these D-values can allow for a target range of particle size distribution during the manufacturing process. The values of the upper and lower ranges should be determined through design of experiment (DoE) studies, or by leveraging prior process knowledge and be included in the drug application for approval.

Conclusion

The manufacturing of OSD pharmaceutical drugs centres around the manipulation of particle size; therefore, it is critical to control particle size from a product reliability and quality standpoint, but also a regulatory point of view. To ensure these targets, the establishment of appropriate particle size specifications with in the process is paramount.

For more information for using PAT, such as Eyecon2 in a regulatory or process use-case, get in touch!