AI In Pharma Manufacturing: Benefits & Uses

How is AI used in the pharma manufacturing industry?

Over the last decade, advancements driven by Machine Learning (ML) a form of Artificial Intelligence (AI) in the pharmaceutical industry is the stuff of exciting sci-fi. A recent report suggests that the AI in pharma market is expected to grow from $699.3 million in 2020 to $2895 million in 2025 at a rate of 32.9%

The benefits from the use of AI in the pharmaceutical industry were highlighted in the aftermath of the pandemic when it catalysed the discovery of effective medicines and vaccines. Researchers were ably aided by AI in disease identification and diagnosis, drug manufacturing, identifying groups for clinical trials, and predictive forecasting, among others, to smoothly roll out vaccines.

Recent Use Cases Of AI/ML In Pharmaceuticals

Recently, a popular podcast on AI discussed how technology was revolutionizing consumer health and pharma sectors. The salient points the discussion hovered around was:

Diagnosis/ Disease Identification

Present advancements in AI are helping researchers to identify small and big problems, ranging from cancer, degeneration in the eye to long-term COVID complications. AI has equipped researchers and healthcare professionals in making giant strides in fields like behavioural modification/personalized medicine/digital therapeutics. Besides, the critical input AI-ML combine offers can translate into greater insights into medical conditions ranging from skin disorders, gum problems to inherited serious diseases. A new development in precision medicine uses AI to run sophisticated computations for treating patients with rare, uncommon responses to treatments.

Predictive forecasting with artificial intelligence and machine learning

Predictive technologies can play a crucial role in forecasting epidemic outbreaks and seasonal illnesses around the world. This could help manufacturers and healthcare professionals optimize their logistics and supply chain. It will also arrange inventories at the right time and in the right quantities to overcome critical shortages.

Clinical trials

We owe a lot to the wonders of digital innovation in the field of AI for the much-needed COVID vaccines. Manufacturers and pharmaceuticals teamed up with IT service providers to use AI in identifying the right candidate for clinical trials. It churned out data on existing diseases, demographics, rate of infection, and other overlapping factors to represent the right group for testing. Several nations ran their pilot runs with the help of AI applications during the vaccine trials.

Additionally, AI with ML can also help drive the digital transformation of pharma companies like it has done for other industries. Marketing technology, supply chain optimization, sales, customer experience management, and advertising technology are some areas where AI can help transform healthcare service providers and manufacturers.

AI in Particle Size Analysis for drug manufacturing

AI with ML have been a great asset to the early adopters – such as those who have been using them for Image analysis in the pharma manufacturing industry. Crucial steps in drug making have been further optimized with the inclusion of software upgrades with AI/ML as their backbone.

For instance, EyePASS the image analysis software for the Eyecon2 particle size analyser now uses a form of AI called Machine Learning to capture real-time data on the size and shape of powders and bulk solids. Such applications have helped troubleshoot and improve end-products. Including automation within a human-machine collaboration approach that has enabled pharmaceutical companies to drive down production costs and minimize risk.

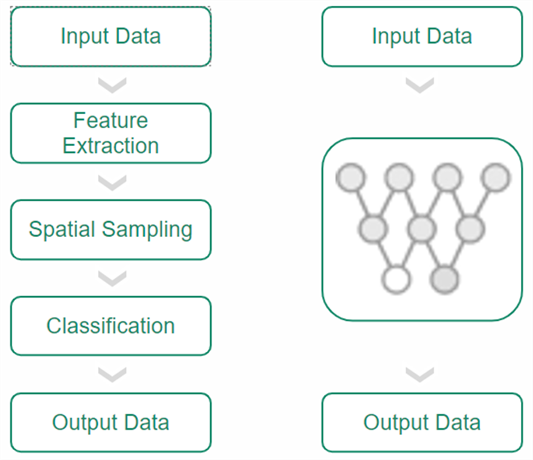

This machine learning approach utilises convolutional neural networks (CNN), a supervised machine learning method where learned features with input data are manually labelled for the task of identifying particles. To break that down a little more, EyePASS images of materials are first labelled manually then a CNN iterates and improves its feature extraction of the images. The features of interest are learned by the network. Increased sets of images are being prepared to expand its capability beyond pharma.

How Does AI and ML Benefit Pharma Manufacturing?

Artificial Intelligence can be programmed to take up several functions, is only limited by nature and the restrictions of its programming. In the pharmaceutical industry, the basics of drug manufacturing dictate that the firm must produce drugs in high quantities to be profitable and recoup development costs. But this requires efficiency and scalability at every step of the manufacturing process. Incorporating AI and Machine Learning in pharmaceutical manufacturing can address most of these issues.

Artificial Intelligence and Machine Learning can bring efficiency to every step of the process starting from research and development to manufacturing and distribution. It can curb shortages by forecasting demand using predictive AI. It is even possible to optimise supply chains with real-time visibility of shipment location, speed, and movement, which can be matched with traffic and weather condition data to predict the right route and an accurate ETA for warehouses.

The application of AI in pharma manufacturing also has several other benefits like;

Optimising Drug Discovery

AI can be a gamechanger in this realm by helping manufacturers with the initial screening of the drug compounds to predict the success rate of the formulations. Precision medicine, next-generation sequencing, and measuring DNA and RNA quickly can be some crucial additions to the process that will help bring drugs faster to the people and offer personalized medicines to critical patients with rare disorders.

A market report projects AI in drug discovery to reach $1,434 million by 2024. The main factors driving this growth would be cross-industry collaborations and ecosystem partnerships, the need to shorten drug delivery time and reduce costs. The growing need for control in the drug development process alongside the increasing use of Cloud-based applications and the impending patent expiry of some of the critical drugs in the world would also drive this growth.

The deep learning capabilities of AI and computation of large amounts of data are key driving forces that make AI in drug discovery a gamechanger. Algorithmic pairings, computer visualizations, and neural networks are helping researchers analyse microscopic images, develop new molecular representations, and even discover new routes for organic synthesis from the literature.

Predictive Quality Analytics (PQA) To Optimise The Production Process

Several pharmaceutical manufacturers are making use of Industry 4.0 solutions like automation and advanced analytics. Solutions like our SmartX automated process control system. SmartX analyses the vast scale of data obtained during the production process and applies advanced data analytics and machine learning to derive critical insights. This enables manufacturers to identify bottlenecks in the process and eliminate unnecessary hurdles; thus, leading to cheaper and more optimised production.

Enabling Continuous Process Verification

As multiple systems in the pharma industry churn out a huge amount of data, it can be challenging for manufacturers to stay on top of their process verification reporting. AL and ML-based solutions come equipped with contextualisation capabilities and deep learning to mitigate the issue with data integration, standardisation, and analysis, thus enabling a Continuous Process Verification CPV environment.

Improves Batch Manufacturing Process

Transfer of data and knowledge from various sources are helping manufacturers improve the batch drug-making process through optimised resource utilisation. From predicting various resources needed for a drug to forecasting the best schedule for manufacturing it, AI offers the best drug manufacturing configuration with minimal waste.

Efficient Quality Assurance and Regulatory Compliance

AI can help spot shortcomings in raw materials even before they enter the production line and thus, main quality and regulatory compliance. Moreover, IoT coupled with AI technology is helping manufacturers spot faulty products, packaging, and machinery.

Is AI The Future Of Manufacturing?

Global Data, which uses an AI deal and patent tracker in the pharmaceutical sector, recently released some interesting insights involving deals with AI or similar tech in the industry over the past nine quarters. The research said though AI is yet to accomplish its full potential, it will be the most disruptive technology in the pharma sector in 2022. There has also been a significant increase in hirings for AI jobs in this sector since, October 2021. According to recent market research, the adoption of AI in the drug discovery market is projected to reach a CAGR of 36.1% during the forecast period of 2021-2031. In 2021, the pharma industry’s top tech investment was in Cybersecurity, followed closely by eCommerce, big data, and AI.

How To Adopt AI and Machine Learning into Your Drug Manufacturing Processes

AI in pharmaceutical manufacturing, after an initial lag, is showing promise and will drive the future of the industry. If you’re a drug manufacturer and are looking to adopt AI and ML technology, InnoGlobal Technology (formerly Innopharma Technology) can help you achieve:

- cost-effective production by using predictive technology for resource optimisation and utilisation;

- faster pharma manufacturing;

- efficient continuous pharmaceutical manufacturing with scalability built in;

- improved batch drug production by optimising every step of the process;

- adherence to regulatory compliance and quality assurance.

Get in touch with our expert team today and discuss your needs. You get the option of renting our equipment before purchasing to test whether our products are the right fit for your business.